Let’s see the most common cast materials.

PLASTER & ACRILYC RESINS:

-Water-based materials are very common in modeling and dioramas.

-They are harmless, do not stain and do not deteriorate the silicone.

-They lack flexibility so we usually need thicker pieces.

-They are porous and absorb moisture. We must assemble them when they have set and dried well. To paint them we should close the pore with some varnish.

-We can harden them by applying polyurethane resin as a varnish or some material that serves as a hardener since the dried plaster absorbs the liquid well.

Common mistakes:

-Make the mixture with a lot of water to avoid bubbles. This mixture results in much more fragile pieces and very long setting times.

-Build and assemble pieces that are still wet. If the pieces still contain moisture, the glue will not be able to penetrate and join the pieces.

POLYURETHANE RESIN & EPOXY

-These resins are really useful and have great properties.

-They attack silicones with use, although the silicone is of high quality, it will also suffer little by little with the use of these materials.

-They are usually toxic, although we only use them from time to time, we should use gloves, glasses and a mask to handle them.

-They are flexible materials so they are ideal for delicate pieces such as miniatures and small details but also for making complete buildings with thin and flexible pieces.

Common mistakes:

-Prepare large quantities. Polyurethane resin sets faster in high concentrations. It is better to apply quantities that allow us to manipulate while it is liquid.

-Stir the mixture for a long time. We only need to mix the components for about 5 seconds. The resin offers us a limited working time, at least 2 minutes, so we should not spend 30 seconds mixing the components!

EPOXY MODELING PUTTY

-Our molds are flexible and we cannot consider them hard.

-Good flexibility helps to release non-flexible materials such as plaster and acrylic resins, but it is also great for releasing chemical resins.

-For solid reproduction materials such as putty, it is better for the mold to be hard. In any case, we can also do it with our molds by introducing small balls of putty and pressing them lightly with an instrument.

………………………………………………………..

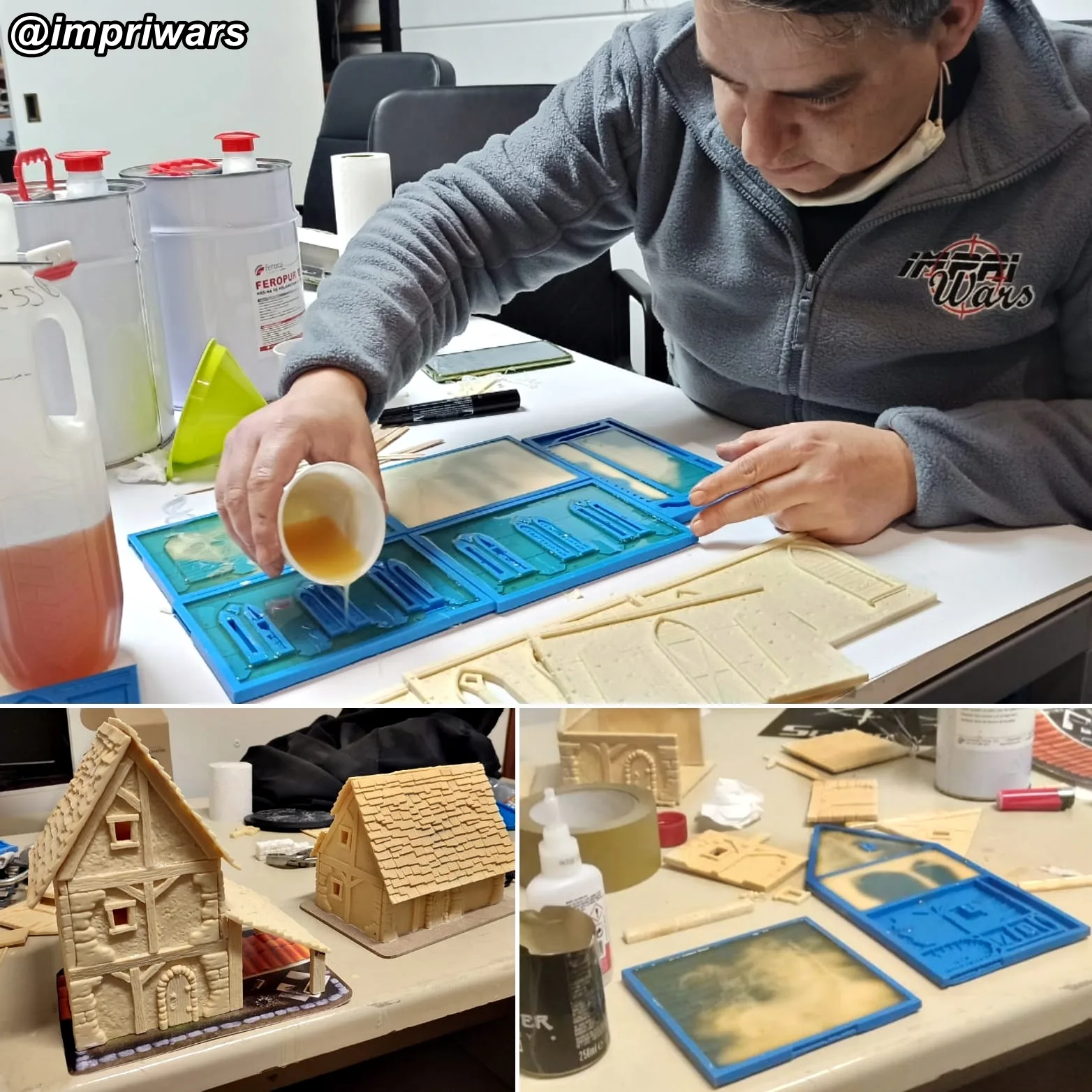

Here we can see our friend Gonzalo from @impriwars using the polyurethane resin. We recommend using protection! although we don’t use it often.

Being a platinum-based silicone, it is a high-end silicone, without shrinkage and with high mechanical and chemical resistance, but it is not indestructible, so chemical resins will always wear down the mold little by little. We can use mold release sprays, talcum powder or Vaseline between pours.

Platinum silicone resists the past of time very well, it does not suffer any shrinkage. We just have to store it without deforming it excessively and away from the sun.

Thank you very much Gonzalo for sharing, please wear a mask, gloves and glasses next time!